Error de formato de correo electrónico

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

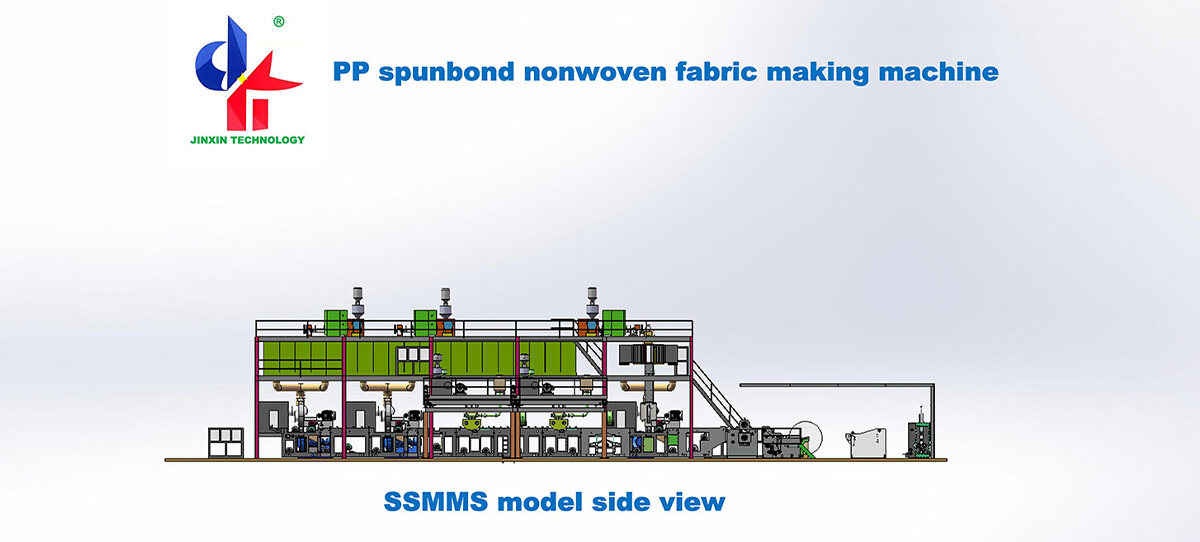

Línea de producción de máquinas no tejidas SSMMS

The non-woven material is constructed of polyester fibers, which can be knitted into varied thicknesses, textures, and hardnesses. The production of non-woven fabrics has transitioned from manual to mechanical as a result of advances in science and technology. Its appearance has resolved complex issues including processing efficiency that is too slow.

| Model | JX-SSMMS | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 60*18*12m | 60*20*12m | 60*25*12m |

| Mechanical Speed | 600m/min | 600m/min | 600m/min |

| Gram Weight | 8-120g/m2 | 8-120g/m2 | 8-120g/m2 |

| Daily Output | 10-16T/Day | 16-25T/Day | 22-35T/ Day |

| Transformer Capacity | ≈1350KVA | ≈1600KVA | ≈2300KVA |

| Power Consumption | 1200°-1850°Ton | 1200°-1850°Ton | 1200°-1850°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Features of non-woven fabric production line

The non-woven fabric is made of polyester fiber and polyester fiber, which can be made into different thickness, feel and hardness through knitting process. With the development of science and technology, the production of non-woven fabrics has changed from manual production to mechanical production. Its appearance has solved the thorny problems such as slow processing efficiency.

The non-woven fabric production line has been summarized by the designer for many years. The air duct adopts the general slit type overall drafting design to ensure the average laying of fibers. The fiber fineness reaches about 3 dan. The product's longitudinal and transverse strength reaches or exceeds the specification. It is equipped with an advanced touch screen control automatic tracking and over temperature and over pressure warning system.

The rolling mill is driven by direct power, hard tooth surface reducer and high stability universal coupling. The bearing adopts the oil cooling overtemperature and oil shortage warning system. The roll surface adopts the peripheral drilling technology to ensure the overall temperature divergence. The box design is advanced, the fluid distribution is uniform, ensuring that the waste products are intermittent, not merged, and have no holes, which improves the product qualification rate. In addition, the spunbonded nonwoven production line is relatively simple and easy for users to use.

Precautions for daily mechanical operation of the nonwoven production line

The mechanical components and maintenance of the nonwoven production line shall not allow too much water and oil to enter the pressure system. To avoid faults, shorten the service life of the cylinder barrel, and ensure the dryness and cleanness of the air, if possible, the refrigeration dryer shall check that when the oil content in each inner cup of the converter is sufficient, the pressure relief valve shall not be used at the rear end for a long time, and shall be pushed. When the work is stopped, the power switch and compressed air control valve shall be turned off; The shaft barrel and all parts shall avoid magnetic loss;

The parts of the side slide seat of the assembly workbench and those with high precision and complexity shall be wiped clean frequently and oiled for maintenance to prevent the accuracy from being affected by rust. Pay attention to the environment and machine maintenance. The environment of the cloth-making workshop induced by cyclophosphamide should be kept clean, especially the printed glass, which needs to be cleaned before work. From an ordinary cleaning and maintenance development, the voltage and power detection should ensure that the voltage is used to avoid too high or too low voltage. It should be set in a cold storage dark room or low temperature, dry place, especially to avoid sinking, Do not use contaminated or touch. Due to the uniform thickness of the rubber eraser, daily production often does not pay attention to this work, which leads to local damage to the cloth-making production board.